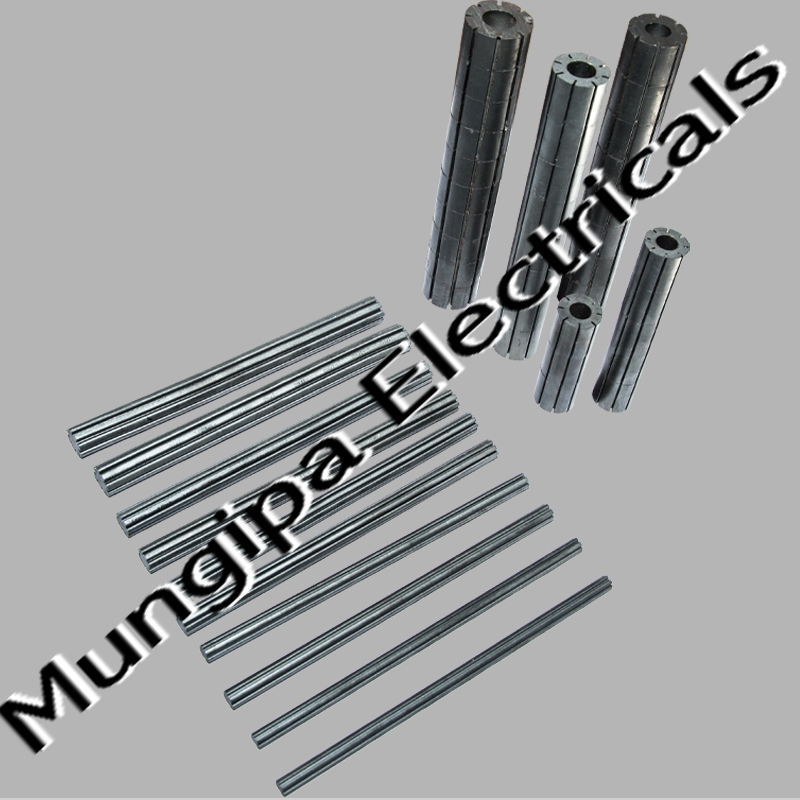

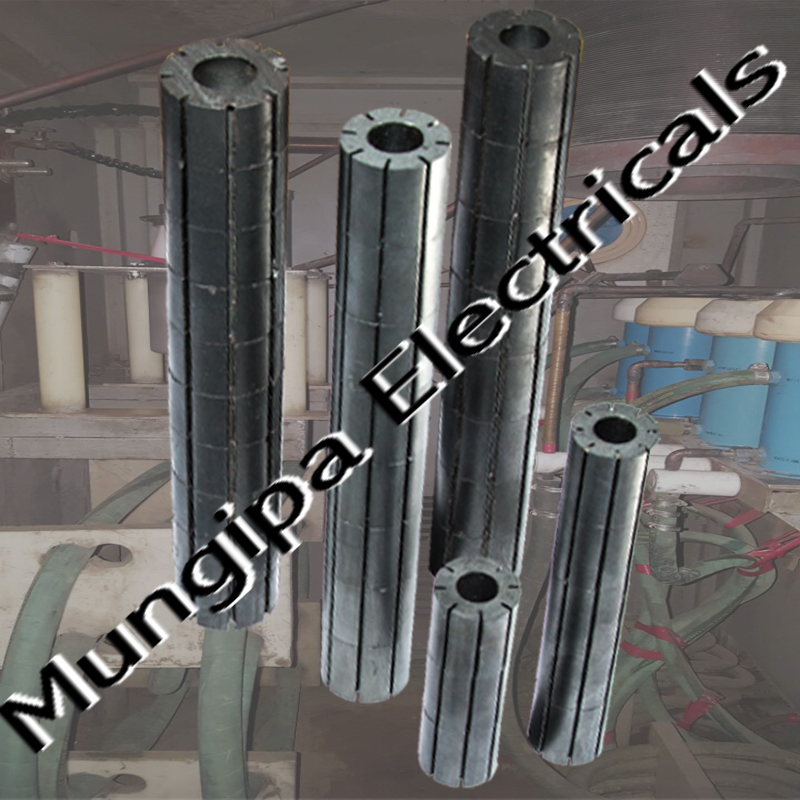

Ferrite Rod

An impeder core / ferrite rod is an essential accessory for the welding of tubes and pipes using high frequency wave guide heating. The characteristic and durability of the impeder core have a significant effect on the efficiency and stability of the welding process. Thanks to advantages in technology and experience gained from manufacturing.

The impeder core concentrates the magnetic flux generated by the work coil into the area of the point joint. Consequently, use of an impeder core massively increases the efficiency of the welding process.

For these applications, special ferrite materials are offered. They are having following excellent physical properties:

- High curie temperature and a low temperature dependence of the initial permeability and of magnetic flux density in the working temperature range.

- A high saturation flux density in the working temperature range upto 150°C

- Low losses with increase of temperature.

- A relative high amplitude permeability.

- A high stability of the initial permeability vs. frequency upto I MHz.

Cores are available in 4 shapes, depending on the application.

Ferrite cores are prepared from a combination of various ferrite materials to concentrate the energy of HF generator into the welding area.Ferrite impeder cores are used for concentration of flux in high frequency RF induction welding of steel tube and pipes. In this application ferrite core experience temperature upto 150°C and the core properties must be optimized for this environment.For this application special ferrite materials are offered.